Vibriertisch für Frischbeton pneumatisch

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Eigenschaften

- Verwendung

- für Frischbeton

- Weitere Eigenschaften

- pneumatisch

Beschreibung

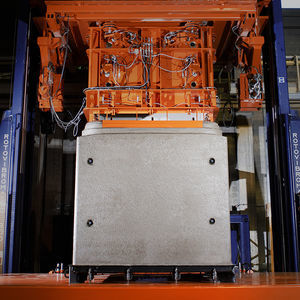

Device for the production of precast elements by means of vibration compaction, with immediate demolding using an overhead crane or forklift, particularly suitable for the realization of special parts. All precast products made of semi-dry concrete that meet the maximum load capacity can be produced, with a maximum height of 2000 mm, as single production (multiple production is also possible on request).

Standard configuration:

The table is equipped with a frame for hydraulic quick clamping of the outer molds (and mechanical quick clamping of the inner molds) with a simple and fast system that allows daily mold changes in a very short time (also eliminates the adjustment of the outer and inner molds after production change).

The concrete supply can be manual (with a simple conveyor belt controlled by the operator with a joystick), semi-automatic (with a conveyor belt with a rotating distributor), or automatic (with a conveyor belt with a rotating second belt controlled by a PC, with software for filling the mold along the outer perimeter). The latter solution is particularly effective for the production of box-shaped and special precast elements.

Other features that make the vibrating table a highly functional system are both mechanical and electronic regulation of the vibration by an inverter and electronic speed control of the conveyor belt (where provided).

The general machine management and control can, upon request for more complex configurations, be carried out via a PC with the Vicom system, with an overview of the machine status and faults, complete with remote maintenance modules.

Products that can be realized:

- All precast elements (with any type of connection) made of semi-dry concrete, with a maximum height of 2000 mm, that meet the maximum load capacity (2 to 42 tons, depending on the various models).

Advantages:

- Cost-effectiveness

- Flexibility (a wide range of products can be manufactured; the machine is ideal for the production of large and, due to its cost-effectiveness and ease of use, medium-sized precast elements)

- High product quality ensured by automatic electronic regulation of vibration and concrete supply

- Extremely fast change of inner molds (the mold can be changed almost immediately due to time savings), without the need to adjust the mold after the change

- Easy to use and maintain

- Possibility to use existing molds, even those not manufactured by Colle

- System does not require foundation work

- Possibility (on request for more complex configurations) of complete control of the system via the PC of the Vicom system, with the possibility of remote production control

Model | Vibrator Group | Damping | Special Features | Total Load Capacity | Payload

1200 x 1200 | 1 vibrator group | Mechanical | - | 3 ton | 2.4 ton

1200 x 1700 | 1 vibrator group | Mechanical | - | 3 ton | 2.2 ton

1200 x 1700 | 2 vibrator groups | Mechanical | - | 6 ton | 5.1 ton

1500 x 2100 | 2 vibrator groups | Pneumatic | - | 6 ton | 4.3 ton

1500 x 2100 | 3 vibrator groups | Pneumatic | - | 9 ton | 7.2 ton

1700 x 2800 | 2 larger vibrator groups | Pneumatic | Self-leveling | 12 ton | 9.5 ton

1700 x 2800 | 3 larger vibrator groups | Pneumatic | Self-leveling | 18 ton | 15.4 ton

2340 x 3000 | 4 larger vibrator groups | Pneumatic | Self-leveling, Hydraulic operation | 25 ton | 20.9 ton

3000 x 5000 | 4+4 larger vibrator groups | Pneumatic | Self-leveling, Hydraulic operation | 50 ton | 41.8 ton

Technical Specifications:

- Production by vibration compaction

- Immediate demolding with overhead crane or forklift

- Suitable for special parts

- Maximum product height: 2000 mm

- Single or multiple production (on request)

- Hydraulic quick clamping of outer molds, mechanical quick clamping of inner molds

- Manual, semi-automatic, or automatic concrete supply

- Mechanical and electronic vibration regulation via inverter

- Electronic speed control of conveyor belt

- Optional PC-based management and remote maintenance

Kataloge

Für dieses Produkt ist kein Katalog verfügbar.

Alle Kataloge von Colle S.p.a. anzeigen* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.