- Produktionsmaschinen

- Kunststoffverarbeitung

- Colle S.p.a.

Pressformen für das Bauwesen Turbomaster series

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Eigenschaften

- Anwendung

- für das Bauwesen

Beschreibung

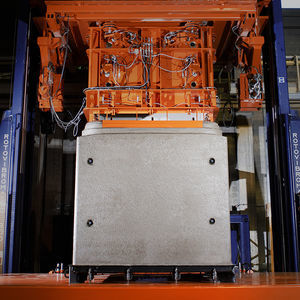

Fully automatic machine for the production of precast elements using the radial pressing process, for heights from 1000 mm to 4000 mm.

Presentation

Fully automatic machine for the production of concrete pipes by radial pressing process with any type of joint. Depending on the different models, the machine can produce precast elements with a diameter from 300 mm to 1600 mm and a variable height from 1000 mm to 4000 mm, with single or double mold.

Technical Features

- The machine can be equipped with a hydraulic quick mold change system, which is simple and quick to operate, allowing for fast daily mold changes. Height control of the precast elements is provided.

- Turbomaster works along the entire length of the precast element with a movable roller head with a rotating end (piston), equipped with distributors to distribute the concrete. The electronically controlled roller head works together with the concrete supply. The compaction rollers rotate in the opposite direction to the smoothing rollers (so that the reinforcements do not twist); the system guarantees the production of pipes of absolute quality, free from defects and perfectly smooth.

- The concrete supply is fully automatic. The conveyor belt brings the concrete to the center of the mold and always calibrates the correct amount: this last aspect is crucial for maximum filling speed and compaction quality.

- The system can be supplemented with automatic handling and storage of the precast elements, as well as cleaning and automatic transport of the base collars and the fitting of the seals. These options allow for further acceleration of the production cycle while reducing the required personnel. The general machine management and control is carried out via a PC with Vicom system, with an overview of the machine status and faults, complete with remote maintenance modules, with the possibility of remote production control (Industry 4.0).

Possible Products:

- Round pipes

- Round pipes with laying surface

- Unreinforced pipes

- Pipes with rigid reinforcement

- Fiber-reinforced pipes

- Drainage pipes

- Socket pipes spigot-to-spigot

- Manhole rings

- Precast elements with any type of joint

Advantages:

- High production

- Low noise operation throughout the production cycle

- Reduced personnel requirements

- High product quality ensured by automatic electronic regulation of the concrete supply, with ascending piston, smoothing and compaction rollers, with built-in distributor rotors

- Extremely fast mold change (the time saved allows the mold to be changed for a possible second shift on the same day), without the need to adjust the mold after the change

- Complete control of the machine via PC with Vicom system, with the possibility of remote production control (Industry 4.0)

Technical Data Sheet:

MACHINE | PIPES | PIPE LENGTH

--- | --- | ---

TURBOMASTER 30/60 | 30 cm – 60 cm | H 100 – 400 cm

TURBOMASTER 30/125 | 30 cm – 125 cm | H 100 – 400 cm

TURBOMASTER 30/160 | 30 cm – 160 cm | H 100 – 400 cm

- Fully automatic machine for the production of precast elements using the radial pressing process

- Production heights: 1000 mm to 4000 mm

- Pipe diameters: 300 mm to 1600 mm (depending on model)

- Single or double mold

- Hydraulic quick mold change system

- Automatic height control

- Movable roller head with rotating end (piston)

- Electronically controlled roller head

- Automatic concrete supply

- Optional automatic handling and storage

- PC with Vicom system for machine management and remote control (Industry 4.0)

Kataloge

Für dieses Produkt ist kein Katalog verfügbar.

Alle Kataloge von Colle S.p.a. anzeigen* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.