- Mechanik - Antriebstechnik

- Antriebselement

- Planetengetriebe

- Shanghai Siheng Motor Co., Ltd

- Produkte

- Kataloge

- News & Trends

- Messen

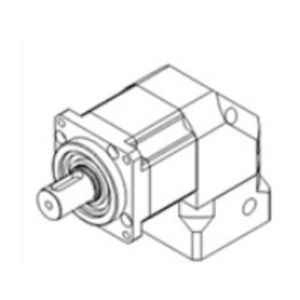

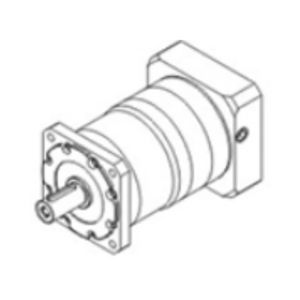

Planetengetriebe WPF42 seriesrechtwinkligmit HohlwelleFlansch

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Eigenschaften

- Typ

- Planeten

- Achsenausrichtung

- rechtwinklig

- Wellentyp

- mit Hohlwelle

- Aufbau

- Flansch

- Leistung

- Präzision

- Weitere Eigenschaften

- großformatig

- Rotationsgeschwindigkeit

Max: 6.000 rpm

(37.699,11 rad.min-1)Min: 2.500 rpm

(15.707,96 rad.min-1)- Untersetzungsverhältnis

Max: 40 unit

Min: 4 unit

- Gewicht

0,7 kg, 0,9 kg

(1,54 lb, 1,98 lb)

Beschreibung

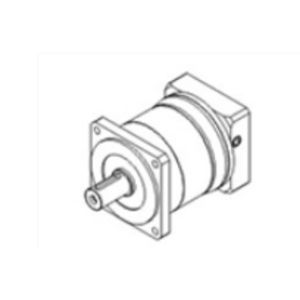

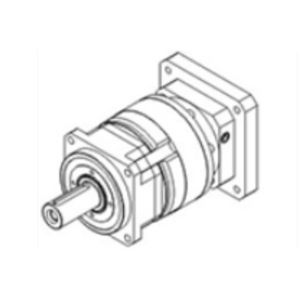

The output planetary carrier of the reducer adopts an integrated nut to eliminate axial clearance design. The front and rear bearings are distributed in a large span within the integral box body, forming a super-strong integrated structure to ensure high torsional rigidity, super-strong radial load-carrying capacity and excellent axial load-carrying capacity. The one-time processing and completion process is adopted to ensure extremely high coaxiality.Outline Dimension Drawing of ReducerMain Technical ParametersLevelFirst stageSecond stageReduction Ratio4/5/816/20/25/32/40Body Length72.284.2Maximum Radial Force280N320NMaximum Axial Force200N240NFull load Efficiency≥90%≥86%Weight0.7kg0.9kgService Life≥20000h≥20000hRated Input Speed2500rpm3000rpmMaximum Input Speed4500rpm6000rpmGear Precision Grade6 GB/T10095 – 20086 GB/T10095 – 2008Operating Temperature–25° ~ +90°–25° ~ +90°Protection GradeIP65IP65Lubrication MethodLong-acting LubricationLong-acting LubricationInstallation MethodFlangeFlangeCategory: GearboxTag: AC servo motor and driverFeatures / Technical SpecificationsIntegrated nut design for eliminating axial clearanceLarge span bearing distribution for high rigidityHigh torsional rigidity and load-carrying capacityHigh coaxiality due to one-time processingReduction ratios: 4/5/8 (first stage), 16/20/25/32/40 (second stage)Body length: 72.2 mm (first stage), 84.2 mm (second stage)Maximum radial force: 280N (first stage), 320N (second stage)Maximum axial force: 200N (first stage), 240N (second stage)Full load efficiency: ≥90% (first stage), ≥86% (second stage)Weight: 0.7kg (first stage), 0.9kg (second stage)Service life: ≥20000hRated input speed: 2500rpm (first stage), 3000rpm (second stage)Maximum input speed: 4500rpm (first stage), 6000rpm (second stage)Gear precision grade: 6 GB/T10095 – 2008Operating temperature: –25° ~ +90°Protection grade: IP65Lubrication method: Long-acting LubricationInstallation method: Flange

Weitere Produkte von Shanghai Siheng Motor Co., Ltd

Getriebe

Verwandte Suchbegriffe

- Getriebe

- Epizyklisches Getriebe

- Konzentrisches Getriebe

- Präzisionsgetriebe

- Rechtwinkliges Getriebe

- Zahnradgetriebe

- Getriebe mit Hohlwelle

- Welle-Getriebe

- Hochleistungsgetriebe

- Flanschgetriebe

- Hochpräzisionsgetriebe

- Flanschmontiertes Getriebe

- Hochqualitatives Getriebe

- Servogetriebe

- Großformatiges Getriebe

- Wasserdichtes Getriebe

- IP65-Getriebe

- Planeten-Servogetriebe

- Servogetriebe mit Vollwelle

- Koaxiales Servogetriebe

* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.