Fördersystem für Umreifungsmaschine für Kartonsfür RollenfördererUmschlag

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Eigenschaften

- Produktanwendungen

- Umschlag, für Kartons, für Umreifungsmaschine, für Rollenförderer

Beschreibung

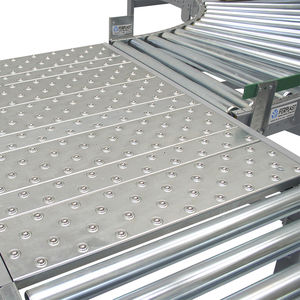

Deflection system with vertical rollers, suitable for changing the feed direction of cartons without the use of pushers or turntables. The system consists of an inclined roller conveyor for gravity discharge of the cartons and two motorized conveyor belts. For example, you can unload the cartons from a strapping or banding machine and deflect them by 380° to bring them back to the operator. With this type of diverter, you can change the way the cartons move in a small space and with few electronic systems, without the use of photocells and PCL (software). The system can be adapted to different conveyor lines as needed and can consist of conveyor belts and deflection rollers of different lengths, sizes, and useful widths. The conveyor belts used have variable speed and are equipped with emergency stop buttons that immediately interrupt operation in case of danger or need. The vertically arranged idler rollers guide the carton and allow it to rotate. The speed of the belts can be adjusted comfortably from 4 to 16 m/min using a potentiometer. - Deflection system with vertical rollers, no need for turntables or pushers - Inclined roller conveyor for gravity discharge - Two motorized conveyor belts - Allows 380° redirection of cartons - Adaptable to different conveyor lines and requirements - Variable speed (4 to 16 m/min) via potentiometer - Emergency stop buttons for safety - Vertically arranged idler rollers for carton rotation Technical Specifications / Features: - Model: SIST-DEV - Description: Carton deflection system with vertical rollers - Speed: Adjustable from 4 to 16 m/min - Motorized conveyor belts with variable speed - Inclined roller conveyor for gravity discharge - Emergency stop buttons included - Adaptable to different conveyor lines

Kataloge

Für dieses Produkt ist kein Katalog verfügbar.

Alle Kataloge von Ferplast anzeigenVerwandte Suchbegriffe

- Zwischenförderer

- Transport-Zwischenförderer

- Riemenförderer

- Horizontaler Zwischenförderer

- Förderer für die Lebensmittelindustrie

- Beschicker

- Rollen-Zwischenförderer

- Elektrischer Förderer

- Schräger Förderer

- Kettenförderer

- Förderer für Handling

- Förderer für Lebensmittel

- Schüttgutförderer

- Förderer zum Ausladen

- Gebogener Zwischenförderer

- Kistenförderer

- Förderer für die Pharmaindustrie

- Förderer für Karton

- Mobiler Förderer

- Förderer zum Laden

* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.