3D-Drucker / Metall Figure 4 135Industrie

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Möchten Sie direkt kaufen?

Besuchen Sie unseren Shop.

Eigenschaften

- Gedruckte Materialien

- Metall

- Verwendung

- Industrie

Beschreibung

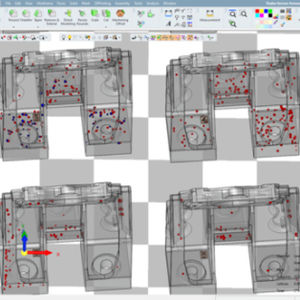

Fast and highly precise 3D printing solutionIf you need to supplement or replace injection mold tooling in the plastic manufacturing process, the Figure 4 135 offers faster, more flexible, and cost-efficient production for both prototypes and small to medium batch sizes. By directly manufacturing small plastic end-use parts, the weeks- or months-long lead time for tooling is eliminated—reducing your time-to-market from weeks to just a few days.Engineers can quickly create prototypes and adapt designs on the fly without retooling. The solution enables companies to manufacture at the highest levels of precision and repeatability, whether for prototypes, small series, custom parts, bridge production, or on-demand spare parts—all without the hassle of tooling costs or inventory management.Speed: Fastest 3D printing technology; projectors cure layers quickly, whether building a single small part or an entire platform of many parts.Accuracy and Repeatability: Powerful projector and image processing IP provide ready-to-use accuracy and repeatability from part to part and printer to printer.Production Ready: Hands-free automatic door for easy access to the print area by operator or robot. Integrated production traceability features. Self-feeding resin tray from a large-volume cartridge.User-Friendliness: Simple operation and maintenance for maximum uptime. Automated functions and preset profiles accelerate and standardize procedures to simplify fleet management.MaterialsFigure 4 resins – see Material FinderIncludes:Diverse set of specialty, durable, robust, rigid materialsLargest selection of flame-retardant (FR) materialsHigh-temperature and elastomeric materialsProduction-Grade ResinsThe Figure 4 135 is designed to operate with the technical and production-grade plastics of the Figure 4 series, delivering printed parts with injection-mold-like quality and top-class smoothness. Choose from a constantly growing range of rigid, robust, durable materials with thermoplastic-like behavior, castable, heat-resistant, and biocompatible materials in many colors and varying translucency. Printed parts exhibit long-term UV and moisture-stable mechanical properties; up to 8 years for indoor use and up to 1.5 years for outdoor use according to ASTM D4329 and ASTM G194 methods.New Hardware ArchitecturePowerful Light Source: High-performance QHD projector with dynamic adjustments and pixel control for repeatable, maximum accuracy and long-term performance.Material Filling: Built-in flexibility for automatic pumping of resin from a 9-kg high-capacity cartridge or manual pouring from a bottle for small batch printing or testing new materials.Clean Interior: All surfaces are flat, seamless, and made of stainless materials tested for the toughest cleaning conditions.Adjustable Screen: 7-inch touchscreen interface adjusts the angle for glare-free visibility. The screen is easy to see for quick task completion.Automatic Door: Choice between foot pedal or user interface-activated automatic door opening and closing saves time, reduces workload, increases throughput, and enables future-proof automation integration.New Software ArchitectureTraceability Features: Track build platforms and parts on platforms; easily track machine ID, material batch numbers, and production date/time.Fleet Management: Manage an entire fleet of printers from a PC or laptop. Intelligent queue management based on material availability and control of print start times.Touch Interface: The HD multi-touch screen displays information for easy visibility to enable faster task completion.Adjustable Screen: 7-inch touchscreen interface adjusts the angle for glare-free visibility. The screen is easy to see for quick task completion.Flexible ManufacturingThe Figure 4 135 can deliver production-quality, series-ready results required to supplement conventional manufacturing processes. With its extremely high precision from the very first moment, the Figure 4 135 solution is ideal for manufacturing industries where a process capability index (CpK) of at least 1.33 or higher* is required for critical processes. The Figure 4 135 significantly exceeds these standards, making it extremely reliable for precision applications. Whether you are creating small quantities of parts for design iteration or filling a platform with large quantities of small components, performance and output remain consistent and repeatable across multiple printers.*Depending on part geometry and feature size.Part QualityThe Figure 4 135 produces exceptional part quality and accuracy, a direct result of proprietary pixel-blending processes combined with precision projectors and innovative hardware configuration. To ensure top-class part quality, all materials, print processes, image processing software, and printer hardware are based on more than 15 years of 3D Systems experience with pixel-based printing, ensuring seamless manufacturing. 3D Systems' image processing software automatically adjusts pixel edges with grayscale methods, resulting in high-quality plastic parts with production-grade surface quality.Figure 4 TechnologyThe Figure 4 135 uses projector-based imaging and contactless membrane technology to quickly build complex, high-resolution parts. Instead of using a laser as in conventional stereolithography (SLA), Figure 4 uses a projector array to cure an entire layer of liquid resin at once. This technology enables high print speeds and high-resolution printing. The high-resolution projector of the Figure 4 135 improves accuracy and precision, enabling the fine details and thin walls required for connectors.3D Sprint SoftwareUse a single software solution for the entire process from CAD to printIncrease efficiency through optimized data managementStreamline time to print and finished part with a single, user-friendly interfaceIncrease productivity and reduce printer downtime thanks to management and monitoring toolsApplicationsDirect production of small plastic end-use partsFlame-retardant (FR) parts for electronics and connectorsThin-walled componentsPrototypes and testingHousings, covers, and snap-fit mechanismsSensorsButtons, grommets, and spacersAdvantagesFastest printing technologyHigh throughput and multiple builds per dayAccuracy and repeatability, from part to part and printer to printerSuitable for series productionAdvanced workflow tools for managing a single printer or a fleetQuick and easy material changeAutomatic door with hands-free operationIndustry-standard durabilityMaterial flexibility for high-performance manufacturingTechnical SpecificationsBuild Area (xyz): 136 x 76 x 165 mm (5.3 x 3.0 x 6.5 in)Resolution: 50 μm pixel sizeProjector Resolution: 2716 x 1528Control Panel: 7" HD display with multi-touchscreenDimensions (W x D x H): 680 x 700 x 1360 mm (26.8 x 27.6 x 53.6 in)Weight: 76 kg (167.5 lbs)Electrical: 100 - 240 VAC, 50/60 Hz, single phase, 5 AOperating Humidity: 30-70% relative humiditySoftware: 3D Sprint for print preparation and monitoringManufacturing Efficiency and Cost SavingsBy supplementing conventional manufacturing of small plastic parts with the Figure 4 135, additional efficiencies and cost savings can be achieved. While injection mold tooling is more suitable for high volumes, other factors must be considered, including extended lead times, upfront investment costs, and high costs for design changes. Once a tool is used, it must be inventoried, stored, and maintained. Compare this to the Figure 4 135, which can be used for prototyping, product development, and bridge manufacturing without limitation on the number of SKUs produced. Hundreds of thousands to millions of dollars can be saved by supplementing a conventional manufacturing process with the Figure 4 135 solution.Validated materials include: Figure 4 Tough 75C FR, Figure 4 FLEX-BLK 20, Figure 4 Tough FR V0 Black, Figure 4 Rigid White, Figure 4 Hi Temp 150C FR BLK, Figure 4 Rigid Gray, Figure 4 PRO-BLK 10, Figure 4 EGGSHELL AMB-10, Figure 4 HI TEMP 300-AMBCompatible materials: Figure 4 Tough 75C FR Black, Figure 4 Tough FR V0 Black, Figure 4 High Temp 150°C FR Black, Figure 4 PRO-BLK 10, Figure 4 Rigid White, Figure 4 HI TEMP 300-AMB, Figure 4 EGGSHELL-AMB 10, Figure 4 JCAST-GRN 20Accessories: Cure 400 post-curing oven (400 x 400 x 400 mm chamber, full-spectrum LEDs, rotating table, compatible with all 3D Systems UV photopolymers)3D Sprint Software: Exclusive software for CAD and polygon data preparation and optimization, and 3D print process managementIndustries: Electronics, automotive, industrial, prototyping, connectors, housings, sensors, and moreCertifications: UL94 V0 flame-retardant materials, biocompatible options, high-temperature resistanceKey Features: Hands-free automatic door, large resin cartridge, advanced traceability, fleet management, high-resolution projector, robust and flexible material compatibility, cleanable stainless interior, adjustable touchscreen, advanced pixel blending for superior part quality

Kataloge

Für dieses Produkt ist kein Katalog verfügbar.

Alle Kataloge von 3D Systems anzeigenMessen

Sie können diesen Hersteller auf den folgenden Messen antreffen

Verwandte Suchbegriffe

- 3D Systems 3D-Drucker

- 3D Systems 3D-Drucker / Industrie

- 3D Systems 3D-Drucker / Kunststoff

- 3D Systems Rapid-Prototyping-Maschine

- 3D Systems 3D-Drucker / Hochleistung

- 3D-Drucker / Hochgeschwindigkeit

- 3D Systems 3D-Drucker / Metall

- 3D-Drucker / ABS

- Additive Fertigungsmaschine / Großformat

- 3D-Drucker / PLA

- Additive Fertigungsmaschine / Dental

- 3D-Drucker / für medizinische Zwecke

- 3D-Drucker / Harz

- 3D-Drucker / Polyamid

- 3D-Drucker / PETG

- 3D-Drucker / für die Raumfahrtindustrie

- 3D Systems 3D-Drucker / SLA

- 3D-Drucker / für die Automobilindustrie

- 3D-Drucker / Nylon

- 3D-Drucker / Pulversintern

* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.